MEASURING WITH ATOS CORE

Measuring with ATOS Core is a basic three-step workflow

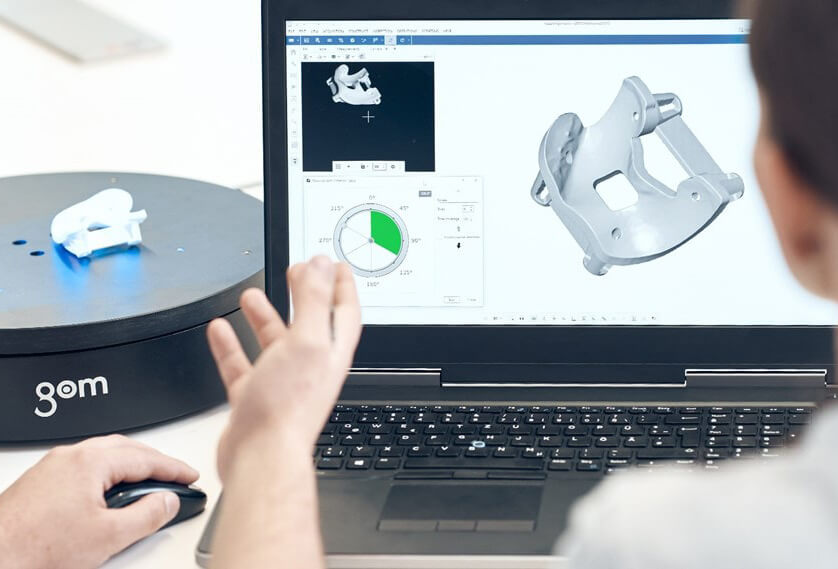

Measurement

Measure your object manually or automatically

No complicated setup necessary

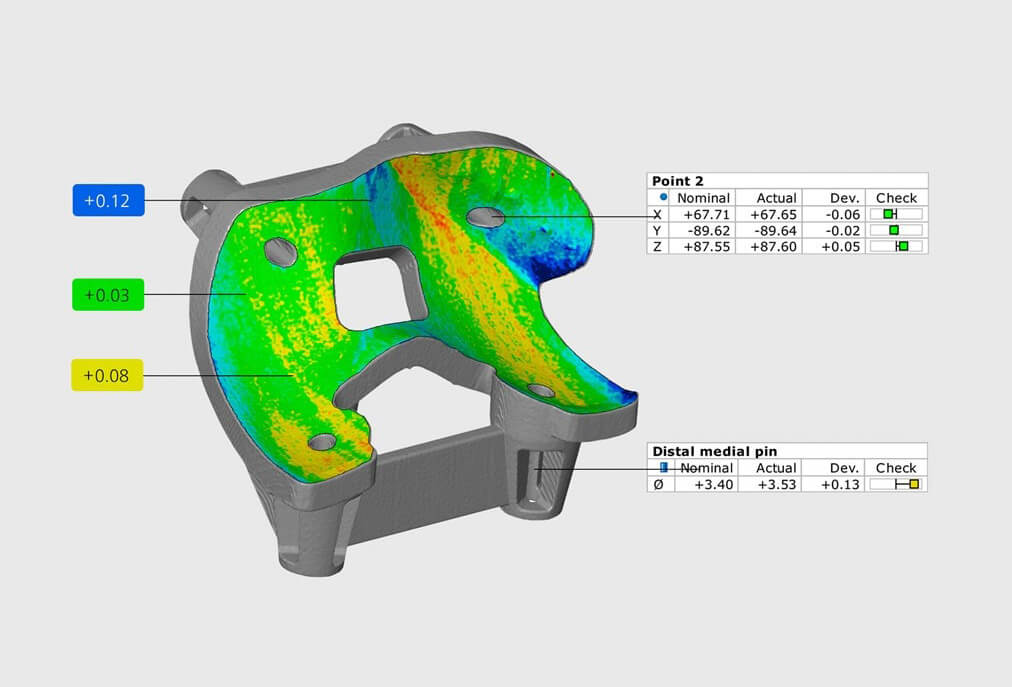

Inspection & Evaluation

From 3D point clouds to polygon meshes

Compare actual scan data with technical drawings or CAD

Results & Reports

Customizable reports with intuitive presentations

Export according to available data standards

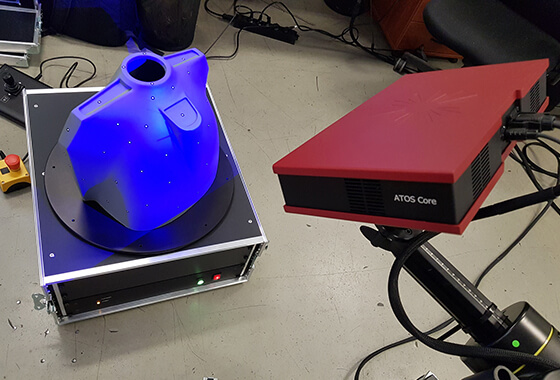

ATOS Core Technology

Optics and electronics are integrated in a very small installation space. Its compact shape gives the sensor high stability and allows measurements to be taken in confined spaces. Depending on resolution requirements and measuring area sizes, the easy-to-handle sensor heads can be replaced easily via a quick release, without the need for recalibration.

Self-Monitoring System

The sensor recognizes changing ambient conditions during operation and can compensate these changes. To ensure the quality of the measuring data, the software of the sensor is continuously monitoring the calibration status, the transformation accuracy, environmental changes and part movements.

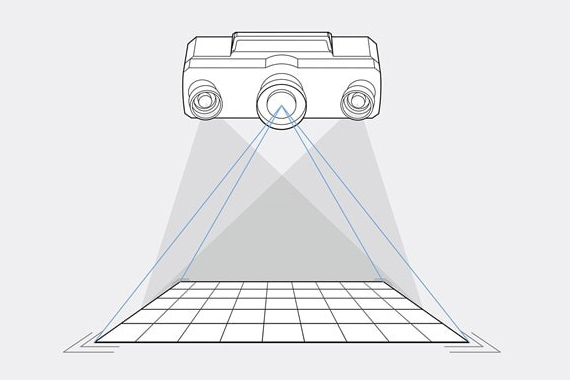

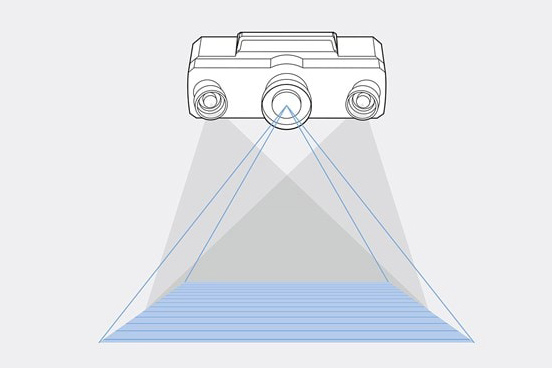

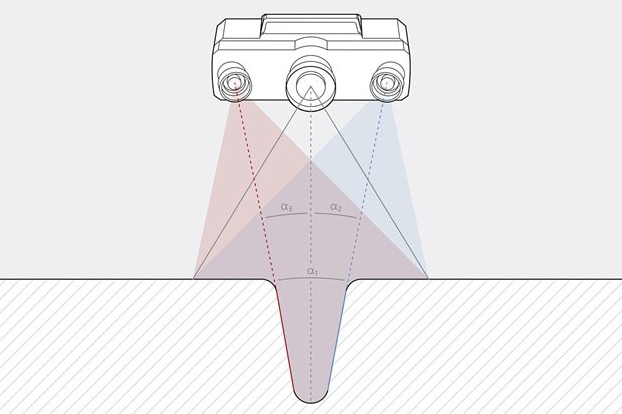

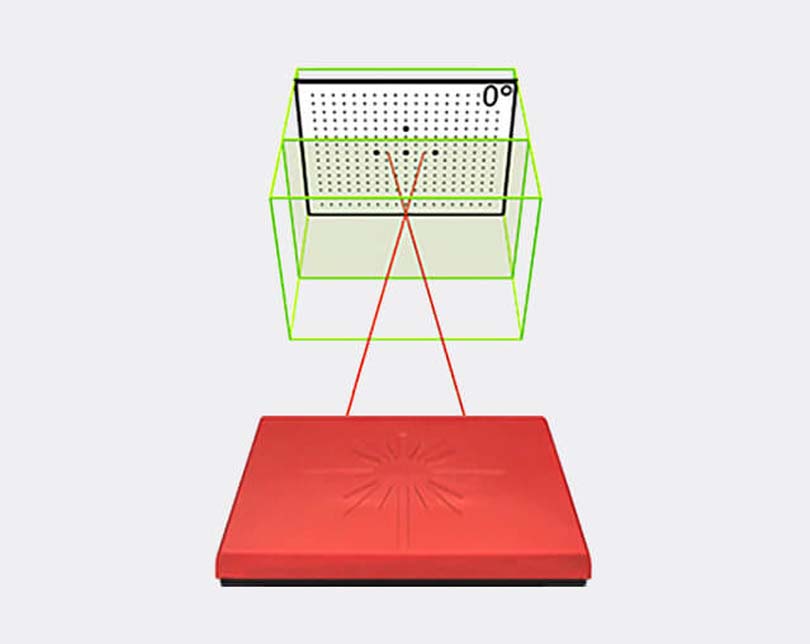

Triple Scan Principle

Together with both cameras, the projection unit operates according to the Triple Scan Principle. During the measurement, precise fringe patterns are projected onto the surface of the object and are recorded by two cameras and the projector unit. Thus, 3D surface points from three different ray intersections can be calculated.

Live Tracking & Part Positioning

In addition to the full-field scanning, ATOS Core systems can also be employed for live measuring of movements and deviations. This tracking is based on the stereo camera principle in connection with the GOM reference point system. Single points as well as complete components geometries can be traced in space. The alignment or positional deviation of a component from the nominal position can and also be measured and tracked live by the ATOS Core. This makes it easier to transfer the virtual alignment of components into reality.

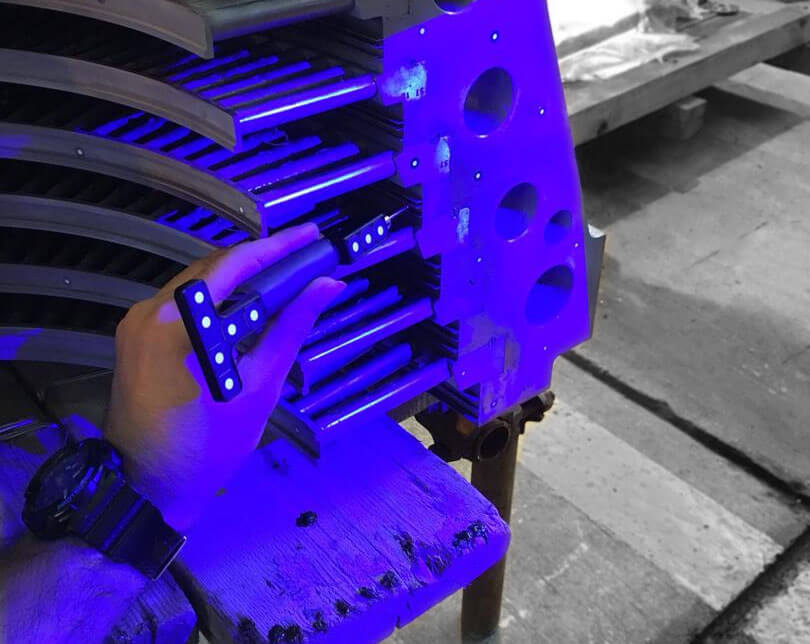

Optically Tracked Touch Probe

Many complex metrology applications require the combination of full-field and point based 3D measurement. The GOM Touch Probe is available as an add-on to the ATOS Core:

- Full-field and point-based 3D measurement

- Measurement of difficult to access areas

- Direct comparison to CAD

- Measurement of primitives

- Quick measurement of individual points

- Online alignment

User Calibrationt

As ATOS Core is delivered pre-calibrated and ready-to-scan, it requires low maintenance. The stereo camera set-up continuously monitors the calibration status. Should the ATOS Core become de-calibrated, the user is immediately informed. ATOS Core can then be quickly and easily recalibrated by the user or automatically with a robot. The sensor does not need to be sent to GOM or one of its partners to be recalibrated, the calibration can be freely carried out by users at any time.

Refrence: www.Gom.com